Floating trash (Image from: http://www.dailygalaxy.com/my_weblog/2007/12/are-there-reall.html)

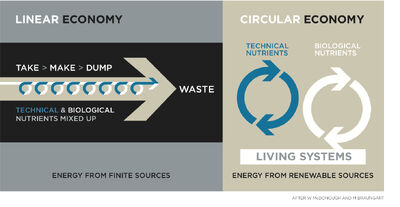

Materials and energy flows in an economy work more effectively by designing out waste (all waste flows become nutrient flows) rather than trying to clean it up after creating it or just reducing the waste by various efficiency measures. Having described this process for the biological cycle there remains the question of materials that do not readily biodegrade. They surely must also cycle, however imperfectly, but the challenge is a little different. Following cradle to cradle thinking, products in this technical cycle are called products of ‘service’ since they cannot be products of ‘consumption’. Can we consume a washing machine, for example?

Perhaps one of the best ways of dealing with products of service is for manufacturers or perhaps retailers to never let go of them. When consumers buy products it’s likely that they will be destroyed, abandoned or lost, too expensive to recover, once the user has finished with them. A more successful approach would be to create a relationship between the user and the materials storehouse (the firm becomes the ‘guardian of stuff’– it’s a function that many firms may come to recognise as the source of their prosperity).

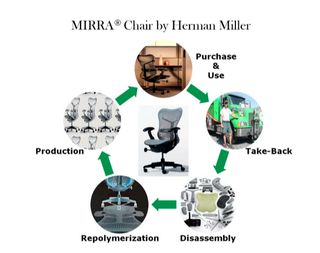

One example of a successful product of service is Herman Miller’s Mirra chair (pictured). The user and the supplier maintain a relationship and the chair and its component parts transition through a system.

The Herman Miller Mirra Chair

This system of products of service can be called renting, leasing, contract hire, licensing, etc. It can be formal or informal, as in many collaborative use schemes but a key element is the role of information and communication technologies to track inventory, monitor performance and reliability and facilitate access. Renting is hardly a new idea but the control technologies are already making a big difference to the potential. The Velib bike share scheme in Paris and the Barclays bike share scheme in London are examples of products of service. New business models abound here as materials and energy costs track higher.

“Today’s goods are tomorrow’s resources at yesterday’s prices.”- Walter Stahel

Materials recovery is driven by rising raw materials prices, supply side risks around scarcity and the increasing benefits accruing to those materials being maintained in as high quality and serviceable a state as possible. Recovering engines for remanufacturing is a great deal more profitable than recovering engines for scrap or even component recovery. Careful design for disassembly and onward use is a characteristic of forward thinking businesses such as Herman Miller (creator of the Mirra chair) or Steelcase (creator of the Think chair).

The point is well made, that the circular economy is not a souped-up recycling economy. Recycling, where it means reducing materials to mashed-up fragments, is more akin to downcycling and that is more akin to having a secondary crude raw material stream in a linear economy than an intelligent approach to value and how to maintain or even enhance materials.

In diagrams, such as the one below, the technical cycle is often shown as a materials cycle floating above the earth. This indicates that the cycle is not via the biosphere as it would be a contaminant in many cases, and it also suggests that the cycle is more often likely to be B-B rather than B-C-B. That break in the ownership to involve the customer is likely to become a feature mostly of products of consumption/biological nutrients.

Furthermore, hybrid products have a mixture of technical and biological materials and good design for disassembly practices are required in order to return both into technical and biological nutrient flows.